The Failure Data Edition is a web based (Internet/intranet) application which collects, consolidate and report failure/repair data from different regions and site locations. The close loop control system provides the ability to track serial numbers and perform as-maintained configuration control during maintenance. It provides the ability to create, dispatch and collect data using the following data forms:

The time between failure and maintenance task data are captured in a Work Order/Job Card System for further analysis. The Work Order and Job Card can be customised to capture client specific data requirements.

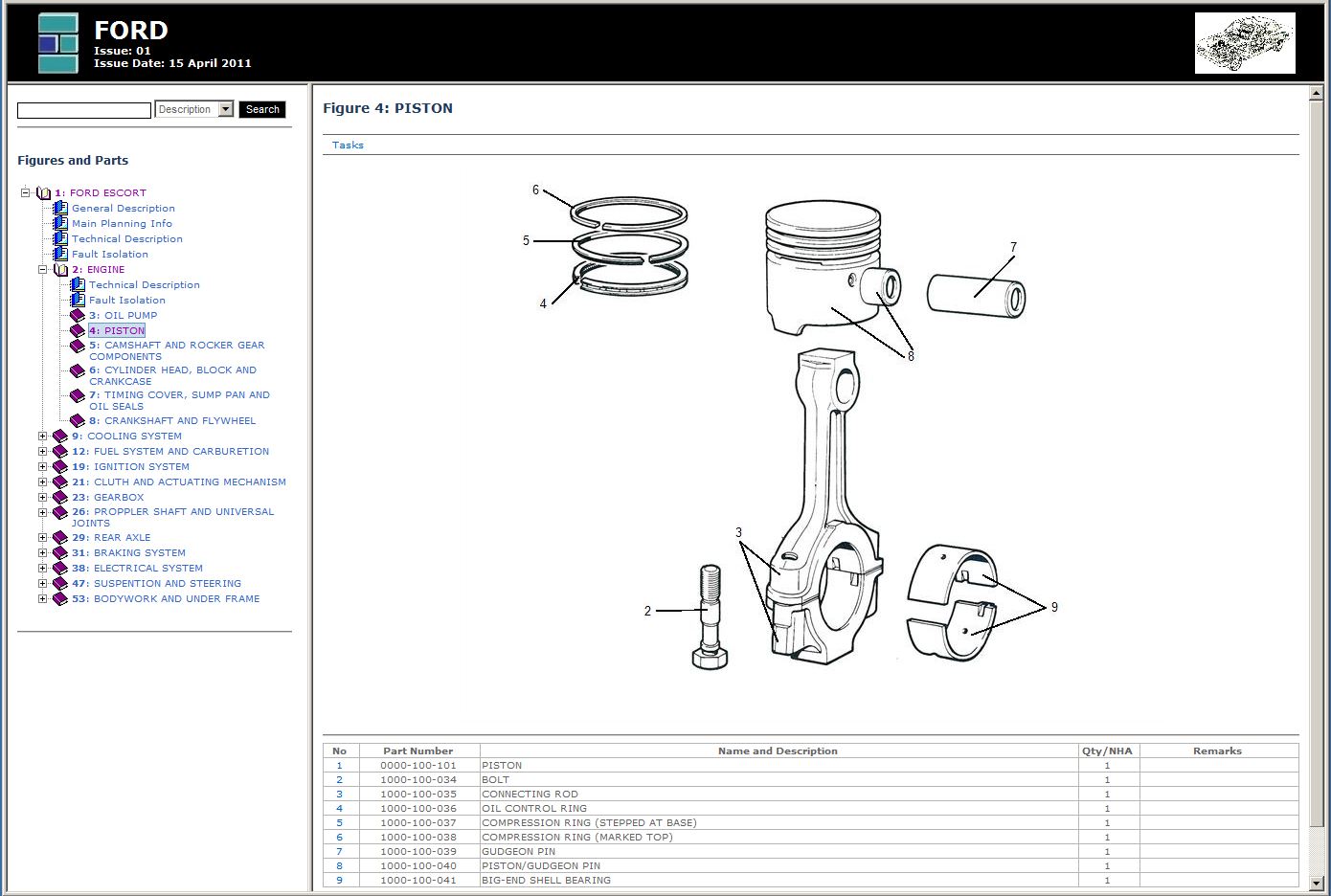

Interactive Electronic Technical Publications, created by the RamLog Information Management Edition are used to assist the maintainer during maintenance and repair procedures. Interactive Illustrated Parts Breakdown Publications are available to the maintainers a store personnel. These IPB’s are used to order spare parts and assist with the assemble/disassembly procedures of complex systems. The following documentation are integrated into the jobcard and spare part ordering processes

Preventative Maintenance activities are scheduled base on calendar or specific operational meters. The time to maintenance are calculate base on the date the activity was performed and a operational prediction made from historical data. The user can create Work Orders from the calendar and setup alerts to send sms or e-mails when maintenance tasks are due.

Inventory is controlled using the following three inventory locations and reponsibilities:

Serial numbers are tracked through the inventory system. The as maintained configuration is controlled using:

The Failure Data Edition has the ability to measure equipment parameters. Thees parameters are grouped into the following three catagories:

Failure condition and equipment status parameters are monitored on a continued basis. Notification in the form of sms or e-mails are send in groups and can be using the notification capability of RamLog.

Running hours and operational meter monitoring and logged into the database. These parameters are used to log failures and calculate reliability and availability parameters. The operational data is also used to determinr the date to the next preventative maintenance action

Conditional parameters linked to an activity

Failure Data Edition (FDE) create a maintenance news timeline available to view during operation. News feeds are generated by:

Notification groups can be created to receive sms/e-mail warnings. Thees, sms and e-mails

The following personnel roles are applicable: